What Is Super Matte Film

Super matte film is a new type of material

Super matte film is a coating that imparts aesthetic features and enhances the performance of the substrate.

The advantages of super matte film

The super matte film not only feels soft and comfortable,

And it has excellent performance, with anti-fouling, scratch-resistant, anti-shrinkage and other properties.

Plus, it has a deep matte finish and looks great.

Application Fields Of Super Matte Film

Super Matte Film Has Broad Market Prospects

Because super matte film have good tactile and visual effects, they are loved and pursued by people. They have become a hot topic in the home decoration, product packaging and base material decoration industries. Especially in the field of furniture painting, super matte film have excellent effects. Performance has become synonymous with the concept of high-end customization and light luxury, and is deeply pursued by home designers. I believe that super matte coating technology will be used in various industries in the future and has broad market prospects!

Wood Board, Furniture

Home Renovation

Decorative Materials

Product Packaging

How To Produce

Super Matte Film?

- Watery Super Matte

- On the work piece with primer, apply UV top coating on roller, press and flatten the top coat with super matte film, and remove the film after curing with UV light source to get the super matte sensitive product with film pressure.

Shortcoming:

Only process plane products

The super matte sense of the product has time limits

High operating costs

- PU Super Matte

- At present, self drying paint (PU, water-based) can achieve super matte feeling effect through paint formula.

Shortcoming:

Using infrared drying requires high power consumption

Environmental protection does not comply with regulations

The film has low hardness and is easily scratched

- UV Super Matte

- Traditional UV uses film pressure or matting powder (agent) plus fluff powder and silicone to achieve inferior super matte effects.

Shortcoming:

Super dumb effect is not good

Construction is difficult

Are you still worried about not finding the ideal production process for super matte film?

Jingke excimer UV curing systems is your best choice!

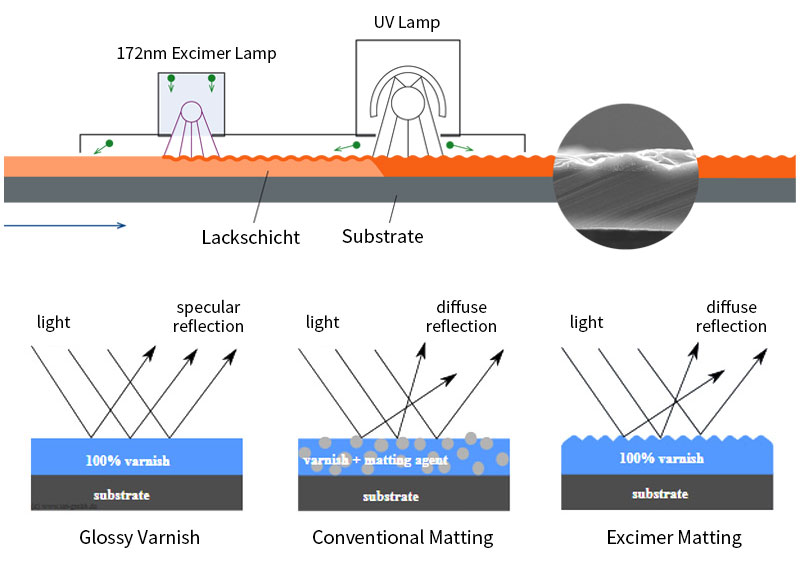

New Technology: Excimer UV Curing System

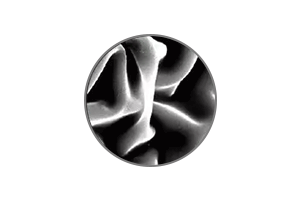

Excimer lamps emit light in the short-wave UV range at a wavelength of 172nm. This light, which is invisible to our eyes, has a particularly high-energy emission. But since it has such short waves, the penetration depth of the UV emission is comparatively low, so that this process leaves a thin film on the wet coating without affecting the deeper layers of coating. Since this film formation is subject to shrinkage, the near-surface film has micro-folds, resulting in a matte surface.These can be cured during final curing using conventional UV curing technology. The result is a mechanically and chemically highly resistant and deep matt surface.

This method of extinction is known as "physical extinction" because it does not require the use of a matting agent. At the same time, the polymerization and cross-linking on the lower surface of 172 nm can provide high surface hardness and high coating density.

Still hesitating? Hurry and seize this opportunity!

- Contact Us:

- [email protected]

Process Of Mattifying By Jingke Excimer UV Curing systems

Jingke Excimer Technology Is Used In Many Industrial Sectors And Applications

-

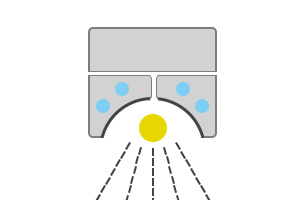

Application

Apply UV paint evenly on the material by curtain or roller.

-

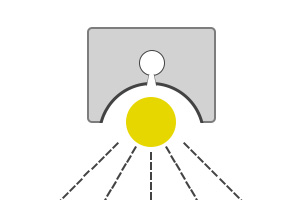

LED Pre-gelling

The UV paint is pre-cured through LED UV lamps, and the paint is initially solidified.

-

Excimer UV Curing

The excimer lamp irradiates 172 nm ultraviolet light onto the paint surface to create a matte effect.

-

Postcuring

The mercury UV lamp performs deep UV curing on the underlying paint.

-

Microfolding

Creates a matting effect and skin feel.

Wet Film

Pre-gell Film

Polimerised urface

Fully Cured Film

Super Matte Film

01

Adopting New Technology:

Excimer Technology

- No matting agent is required, matting and thorough curing are performed as one process step.

- The super matte film is more superior, good touch, increased surface hardness, improved chemical resistance, and improved wettability.

02

Complete Excimer UV Systems

- We provide a complete set of excimer UV systems, including light sources and control systems, nitrogen control systems and devices, which can be customized on demand and can be installed to produce skin-sensitive films.

- We use imported mercury-free excimer lamps, multi-stage drying, highly matte, breathable, environmentally friendly, and easy to construct.

03

Cost-effective

High Quality, High Performance- Imported light source and patented technology, the excimer system operates with high efficiency and high quality.

- Production costs and machine investment costs are greatly reduced.

04

Company Strength Is Abundant

- More than fifteen years of experience in the UV curing industry, thousands of successful UV equipment installation cases. Products are widely used in offset printing, coating, flexo printing, labels and various industrial curing applications.

- Jingke has experienced professional engineers who can provide customization and design according to customer needs to provide you with satisfactory excimer system solutions.

05

Excimer Super Matte Film Has Superior Performance

Visible Good QualityExcimer technology

Skin touch

Super matte surface

Anti-fingerprint

Scratch-resistant

Resistant to dryness and wetness

Sun protection does not discolor

Waterproof and moisture-proof

Minor scratch repair

4H hardness

Firmly attached

Easy to clean

Temperature difference resistance

Formaldehyde-free

Chemical resistance

Jingke Provides You With One-stop Super Matte Film Production Process Solutions

JINGKE UV

about usABOUT USCompany Profile

Zhongshan Jingke Printing Equipment Co., Ltd. is a manufacturer of UV curing equipment integrating design, research and development and production, and has been recognized as a national high-tech enterprise. The company is located in the port town of Zhongshan City, plant area of more than 4000 square meters, with a number of advanced UV curing system processing and production equipment.

View DetailsMarketingmarketing

Focus on the R&D, manufacturing and production of UV curing systems, providing global sales and customized services.

Serviceservice

Professionalism, innovation and advancement, creating value for customers and creating wealth for society.

Purposepurpose

Constantly challenge ourselves to strive for excellence and provide customers with UV curing equipment solutions.

Zhongshan Jingke Printing Equipment Co., Ltd. © Copyright 2024

TEL:+86 760-88498235 FAX:+86 760-88498239

E-mail:[email protected]

Address:NO.9 Shagang East Road, Gangkou Town

Zhongshan City, Guangdong Province, China

- Home|

- Cases|

- Products|

- News|

- Contact Us|

- About Us|

- Sitemap|

- XML Sitemap|